Equipment

Babcock Borsig Steinmüller..:: Read More ::..

Babcock Borsig Steinmüller

Babcock Borsig Steinmüller offers as a globally-active service provider in the power plant technology and environmental engineering sectors, a wide range of life-cycle services for steam generators and power plant components, including: construction, maintenance and repair, modernization and rehabilitation, retrofit and deconstruction, performance and efficiency enhancement, service life extension, emission reduction, repair and spare parts. The company's service range is focused primarily on fossil fuel power plants, industrial power plants, chemical and petrochemical facilities, smelters and steel production plants, waste incineration plants and combined-cycle power plants.

- Construction of steam generators (SG) and steam generation components

- Modernization, conversion of SG and SG components

- Key turning mills, beater wheel mills

- Firing systems

- Heat displacement systems, cooling systems

- Air pre-heaters

- Assembly of new plants and plant components

- Maintenance, service, inspection and repair

- Spare parts and manufacturing of pressure parts as well as selected components.

- Service life studies, plant diagnosis modernization concepts.

Burner shut-off valves, shut-off Valve of solid, liquid and gaseous fuels..:: Read More ::..

Burner shut-off valves, shut-off Valve of solid, liquid and gaseous fuels

The burner shut-off valves in power plants need to function with absolute Reliability to ensure smooth and trouble-free operation at all times. KÜHME manufactures valves for the fast, reliable shut-off of solid, liquid and gaseous fuels.

Emergency Shutdown Valve (ESD)..:: Read More ::..

Emergency Shutdown Valve (ESD)

The burner shut-off valves in power plants need to function with absolute Reliability to ensure smooth and trouble-free operation at all times. KÜHME manufactures valves for the fast, reliable shut-off of solid, liquid and gaseous fuels.

Intake Pump..:: Read More ::..

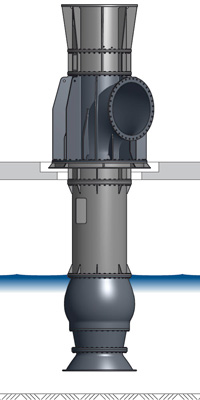

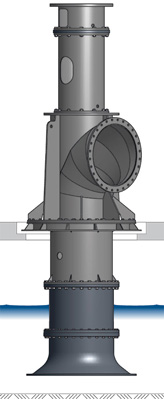

Intake Pump

Mixed flow pumps convey pure or lightly contaminated fluids, typically in pumping stations for precipitation and mixed water, hydroelectric power plants and other power plants, in docks and locks as well as in industrial water supply systems.

Bar Screening - Claw Screen..:: Read More ::..

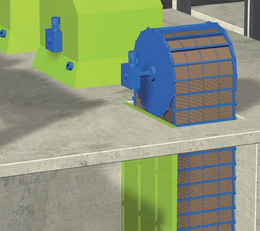

Bar Screening - Claw Screen

Claw Screen is usually installed as a first cleaning step in water intakes and at the inlet of pumping stations. This machine is best suited to removing bulky debris and very large obstacles from a bar screen.

Bar Screening-Revolving Chain Screen..:: Read More ::..

Bar Screening-Revolving Chain Screen

Due to various cleaning elements, revolving chain screens can be adapted to particular tasks such as the removal of jellyfish, sea grass and fish. Simple and robust construction combined with modern design and manufacturing technologies ensures high reliability and a long service life thanks to low maintenance requirements.

Bar Screening- Cable – Operated Grab Cleaners-Stationary and Traversing..:: Read More ::..

Bar Screening- Cable – Operated Grab Cleaners-Stationary and Traversing

Stationary Cable-Operated Grab Cleaners are installed as coarse or fine screens in pumping stations or inlet works of sewage treatment plants. In industrial plants, power plants and pumping stations, they fulfill the first cleaning stage in the treatment of industrial, process and cooling water. In hydroelectric power stations they protect the turbines. Their main purpose is the removal of bulky screenings and sediment material such as sand, gravel and debris, and hence the protection of downstream equipment.

Bar-Screening- Cable – Climber Screen..:: Read More ::..

Bar-Screening- Cable – Climber Screen

Suitable for both coarse and fine screening, as either a front or back-raked screen, the GEIGER® Climber Screen has proven successful for decades, especially in the area of wastewater applications.

Fine Screening – Multidisc Screen..:: Read More ::..

Fine Screening – Multidisc Screen

The MultiDisc® Screen as a special compact unit is installed within the intake chamber across the direction of the water flow.

Fine Screening-Center-Flow Travelling Band Screen (In-To-Out Flow Pattern)..:: Read More ::..

Fine Screening-Center-Flow Travelling Band Screen (In-To-Out Flow Pattern)

As the last cleaning stage for water intakes, finest screening is of particular importance to protect downstream equipment such as pumps and condensers reliably against clogging. Travelling Band Screens have, for decades, been operating successfully in water intake systems in power stations, petrochemical and sea water desalination plants, steel works and other industrial plants all over the world.

Fine Screening-Dual-Flow Travelling Band Screen (Out-To-In Flow Pattern)..:: Read More ::..

Fine Screening-Dual-Flow Travelling Band Screen (Out-To-In Flow Pattern)

As the last cleaning stage at water intakes, finest mesh screening is essential to protect downstream equipment such as pumps and condensers from damage caused by debris and large sediments. For decades, GEIGER® Dual-Flow Travelling Band Screens, have been operating successfully in the water intake systems of power stations, petrochemical plants and sea water desalination plants, steel works and other industrial plants all over the world.

Fine Screening – Microscreen..:: Read More ::..

Fine Screening – Microscreen

The centerpiece of the PASSAVANT® Microscreen MTSM is a rotating drum consisting of mesh baskets that are mounted together. The mesh baskets are covered with polyester screening mesh. The Microscreen MTSM can be installed in a concrete chamber or in a steel or plastic casing.

Fine Screening –Johnson Passive Intake System..:: Read More ::..

Fine Screening –Johnson Passive Intake System

The JOHNSON Screens® high capacity passive intake screens are constructed using non-plugging Vee-Wire® with a patented internal dual flow modifier that creates a nearly uniform low velocity flow through the entire screen surface.

Shut Of Devices..:: Read More ::..

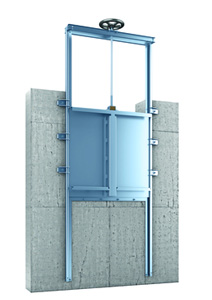

Shut Of Devices

On the occasion of the development and production of shut-off devices, Bilfinger Water Technologies looks back on more than 100 years of experience.

Stop Logs..:: Read More ::..

Stop Logs

Stop Logs are most commonly used to isolate intake channels at power plants, refineries, industrial plants or desalination works for maintenance purposes.

Electric Fish Repelling System..:: Read More ::..

Electric Fish Repelling System

In recent years the protection of fish, animal and aquatic life has become a key-issue for the design and operation of water intakes which take water from rivers, lakes and the sea. The new rules can affect intakes used for cooling or process water as well as hydroelectric power.

Behsan Parsian Sanat Company Ltd. is a manufacturer’s representative company head-officed in Tehran, providing nationwide sales and client support throughout Iran; having international offices located in Vancouver, Canada.

Behsan Parsian Sanat Company Ltd. is a manufacturer’s representative company head-officed in Tehran, providing nationwide sales and client support throughout Iran; having international offices located in Vancouver, Canada.