Packaging Machinery

Blister packaging machines..:: Read More ::..

|

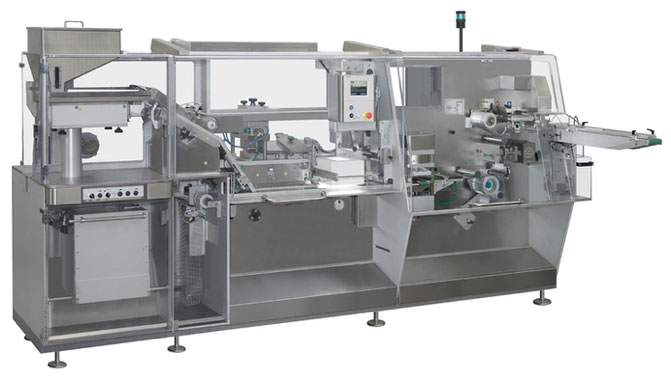

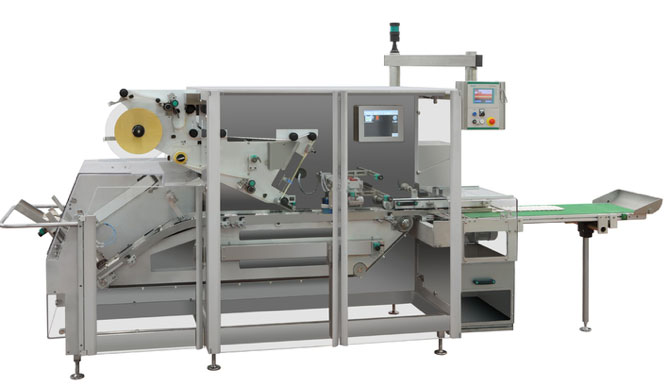

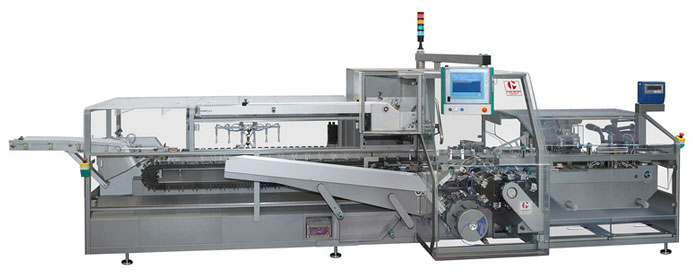

MB421 Suitable for small and medium production batches to process blisters made of PVC+Aluminum, Aluminum+Aluminum, Polypropylene, PET and PVC, Aclar, COC |

|

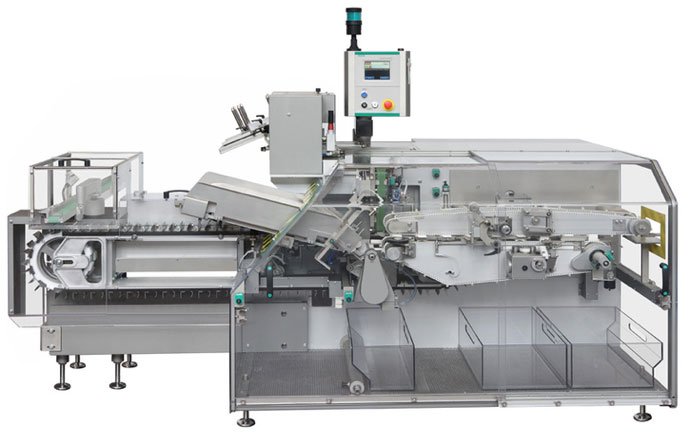

MB460 Continuous motion thermoformer suitable to put use blisters made of PVC+Aluminum, Aluminum+Aluminum, Polypropylene, PET and PVC, Aclar, COC Forming unit at the back of the machine to offer maximum layout compactness and to clearly separate the material processing zone from that where the products run |

|

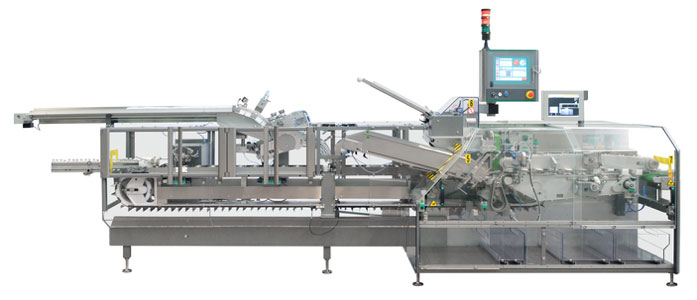

MB451 Evolution Automatic thermoformer designed to produce PVC+Aluminum, Aluminum+Aluminum, Polypropylene, PET and PVC, Aclar |

Sachets..:: Read More ::..

Tablet counter & capping machines..:: Read More ::..

|

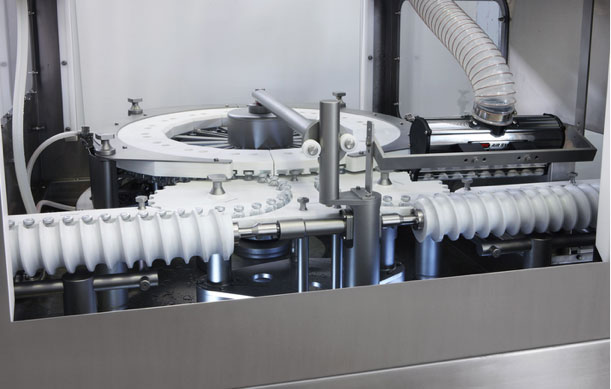

FTC12 Designed to automatically count tablets, coated tablets, hard and soft gelatine capsules, lozenges Brushless drive for the various machine function to ensure maximum operational management |

|

COMPACT12 Mechanical speed would be up to 60 cycles/minute. Automatic counting and capping Monobloc Intermittent motion suitable to count tablets, capsules, oblong tablet and closed bottles with screw caps, Alu caps, or press-on caps. |

|

ELECTRA Electronic counting and filling machine Combination of volumetric filling system and electronic control system Sensor to check the right counting and camera vision system to check product integrity Reliable feeding system |

|

FTC24 This machine is an electronic counter with two totally independent counting units which are perfectly integrated in the compact and solid bed which can count almost any kind of product without having to change size parts. The speed up to 100 strokes/minute |

|

ML667 New Rotary continuous motion capper equipped with one turret suitable to insert silicagel, and close the containers with a screw cap. |

|

ML55 Automatic capping machine, intermittent movement, equipped with one plugging unit suitable to close glass or plastic bottles The level of bottle transfer is 200 mm from the machine level to allow easing cleaning |

|

SIRIO3ROB Mechanical speed would be up to 200 bottle/minute, suitable for round or square shape bottles Bottle height 30-200 mm |

Rigid tubes packaging machines..:: Read More ::..

Strip packaging machines..:: Read More ::..

|

MST200 Machine designed to package solid products in strips, to be connected in line with downstream cartoning machine. The mechanics speed is 100 horizontal cuts/minute. Number of channel from 4 to 8 maximum |

|

MST200 Mini Automatic machine suitable to pack solid products, like tablets and/or dragées, caplets, capsules and effervescents etc. in sealed strips, for stand-alone installation. Number of channels from 4 to 8 maximum. |

Stickpack forming and filling machines..:: Read More ::..

Pharmaceutical blowing machines..:: Read More ::..

|

Marchesini offers a wide range of blowing machines. SW12, SW16, SW24, SW32: SCL12: |

Pharmaceutical washing machines..:: Read More ::..

|

WR24 Continuous motion machine for internal and external washing and drying of ampules, vials, and cartridges. Mechanical speed of 24 000 pieces/hour |

|

WR16 Continuous motion machine for internal and external washing and drying of ampoules, vials and cartridges. Mechanical speed of 12 000 pieces/hour with 4 grippers and 6 000 pieces/hour with 2 grippers |

|

WRE 24 Continuous motion machine for washing and drying ampoules and vials (externally). Mechanical speed of 24 000 pieces/hour |

Pharmaceutical sterilization tunnel..:: Read More ::..

Pharmaceutical filling and capping machines..:: Read More ::..

|

ML642 Intermittent motion monobloc suitable for filling and capping plastic and glass bottles, designed for the pharmaceutical and cosmetic industry. |

|

ML646 Automatic filling and capping machine suitable for filling and capping plastic and glass bottles, designed for the pharmaceutical and cosmetic industry. |

|

ML618/2T High speed rotary monobloc machine, suitable to fill and cap vials (2 closures), designed for the pharmaceutical sector according to cGMP requirements. |

|

OPTO 150 This machine is a brand new modular filling and capping machine with 3-6 dosing pumps and 1 or 2 capping units, designed to handle either plastic or glass bottles and suitable in particular for ophthalmic products (capacity up to 30 ml). |

|

ML661 Linear monobloc machine for Filling/Capping vials; |

Pharmaceutical aseptic liquid filling and closing machines..:: Read More ::..

|

Stery LC Stery LC is a filling and stoppering machine for liquid or lyo products, suitable to fill small parenteral volume vials (SPV) in a sterile environment with complete or partial closure using rubber stoppers. |

|

CAPSY (new) Alu Cap sealing machine for liquid or lyo products, suitable to close Small Parenteral Volume vials (SPV). |

|

ML670 High speed rotary sealing machine, suitable to apply and seal aluminium caps by means of a rail. |

Pharmaceutical ampoules filling and sealing machines..:: Read More ::..

Pharmaceutical syringe filling and closing machines..:: Read More ::..

Pharmaceutical syringe handling machines..:: Read More ::..

|

FREETUB 10 New New automatic tub opening unit with automatic loading system of the sealed tub. The unit consists of a station that heats the edge of the tub and of a robotic station that opens it. |

|

FREETUB 20 New Automatic Deliding Unit for opening sealed tubs |

|

NEXTRA N10 The Nextra N10 is a machine for removing disposable syringes from nests. |

|

NEXTRA T20 The Nextra T20 is a machine for removing syringes or safety devices from trays, pre-arranged to be connected in line with other machines. |

|

NEXTRA B30 The Nextra B30 is a machine for buffering syringes with F.I.F.O. process, pre-arranged to be connected in line with other machines. |

|

NEXTRA T25 Retrayer for syringes and safety devices in tray. |

|

NEXTRA N15 Machine for handling syringes and for filling the nests inside the tubs. |

|

MS701 Buffering machine for syringes. |

Pharmaceutical syringe assembling machines..:: Read More ::..

|

COMBI 1 BS Continuous motion machine for assembling syringes with backstop, pre-arranged to be connected in line with other machines. |

|

COMBI 3 BS Continuous motion machine for assembling syringes with plungers and backstops and for labelling them, pre-arranged to be connected in line with other machines. |

|

COMBI 1 SD Continuous motion machine designed to assemble disposable syringes with safety device, pre-arranged to be connected in line with other machines. |

|

COMBI 3 SD Continuous motion machine designed to insert the plunger, to apply label and finally to assemble the Safety Device on the syringe, pre-arranged to be connected in line with other machines. |

|

COMBI 1 LAB Continuous motion machine designed to label syringes, pre-arranged to be connected in line with other machines. |

|

COMBI 1 P Continuous motion machine designed to apply a self-adhesive label around disposable syringes, pre-arranged to be connected in line to other machines. |

|

COMBI 2 PL Continuous motion machine designed to assemble disposable syringes with plungers and to label them with self-adhesive labels, pre-arranged to be connected in line with other machines. |

|

COMBI 2 PL NO CONTACT New Continuous motion robotized machine designed to assemble disposable syringes with plungers and to label them with self-adhesive labels, pre-arranged to be connected in line to other machines, in No-Contact execution. The syringes never get in contact with each other. |

Mascara packaging machines..:: Read More ::..

Squeezable tube packaging machines..:: Read More ::..

|

Colibrì Automatic tube filling and capping machine Suitable for any tube type by making simple adjustments; Fast and tool-less size changeover; Excellent access for cleaning and maintenance; Quick interchangeabilitry of closing groups; Electronic dose adjustment with the possibility of memorizing up to 50 dose |

|

Millennium 120 The Millennium 120 is a single-channel linear automatic filling and closing machine for metal, plastic and laminate tubes. |

|

Millennium 200 This machine is a twin-channels linear automatic filling and closing machine for metal, plastic and laminate tubes. |

Jar packaging machines..:: Read More ::..

Pharmaceutical serialization..:: Read More ::..

|

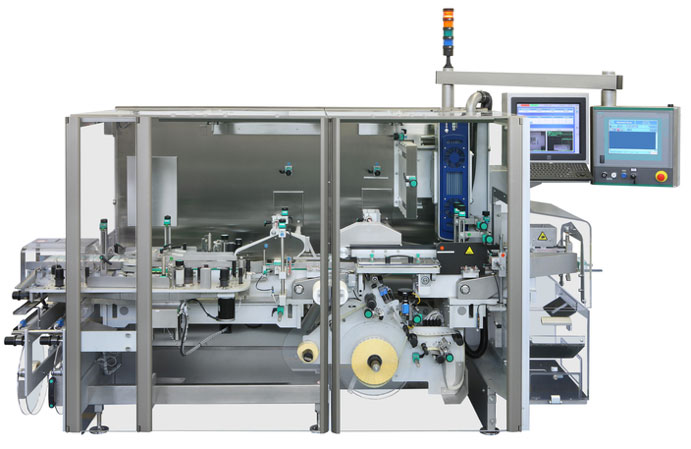

BL-A309 Automatic labeller for the application of one vignette label on the upper panel of carton. Machine designed to allow the installation of tracking devices as inkjet or laser printers plus corresponding cameras, to print and subsequently verify 2D codes and relevant human readable characters, on the lateral flaps and on the upper panel. |

|

BL-A415 Automatic labeller for the application of one vignette on the upper panel of carton or as alternative of two self-adhesive, tamper-evident seals on the closure points. Mechanical speed: 400 pcs/minute |

|

BL-A420 Automatic labeller for the application of one vignette label on the upper panel of carton and of two self-adhesive, tamper-evident seals on the closure points and as alternative one vignette on the upper panel and/or one on the bottom panel. |

|

BL-A430 Automatic labeller for the application of one vignette label on the upper panel of carton, one on the bottom panel and two self-adhesive, tamper-evident seals on the closure points. Machine designed to allow the installation of tracking devices as inkjet or laser printers plus corresponding cameras, to print and subsequently verify 2D codes and relevant human readable characters, on the lateral flaps and on the upper panel. |

|

BL400VA TT Automatic machine suitable for the application of a vignette label or similar on flat cartons. Printing systems on the upper face for 2D code (Data Matrix) and of human-readable data, with quality camera control. |

Pharmaceutical cartonern..:: Read More ::..

|

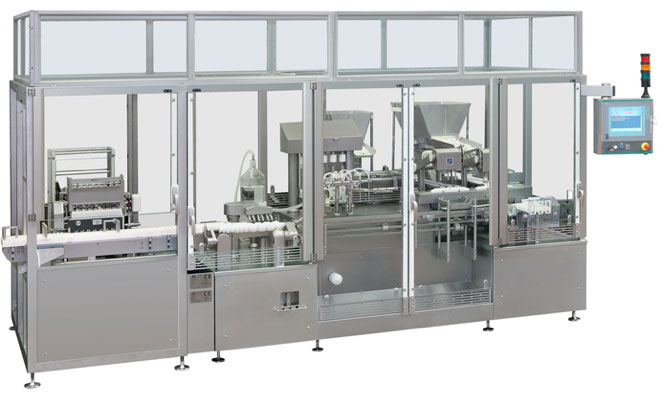

BA100 Horizontal intermittent motion cartoner, specifically designed for medium production rates cartoning applications. The machines is suitable for the pharmaceutical, cosmetic, food and consumers products industry. |

|

MA50 Automatic intermittent motion horizontal cartoning machine, very compact and reliable. |

|

MA80 New Automatic intermittent motion horizontal cartoning machine, very compact and reliable. The working area is in cantilever (balcony type) layout. The main structure has a vertical partition to separate the mechanical section (rear) from the working area (front). Inclined surfaces on the lower part of the machine transport discarded products and cartons towards the operator into proper collecting bins, for a complete clearance of packing residues and easy machine cleaning. MA 80 is suitable to pre break and erect three-flap straight or reverse tuck cartons, insert product, which has been delivered to the infeed bucket chain, close cartons and discharge. |

|

MA100 Intermittent-motion horizontal cartoner, entirely made with balcony construction, designed around three concepts: versatility, ergonomics and maximum efficiency in a small footprint. |

|

MA100 EXP Intermittent-motion horizontal cartoner, entirely made with balcony construction, designed around three concepts: versatility, ergonomics and maximum efficiency in a small footprint. With the EXPERIENCE line of machines, a product is packed only after its verification as well as conformity of carton, leaflet or other items. If non-conformity is detected, the product waits for the correct component and, only then, proceeds with automatic packing. |

|

MA155 Continous motion horizontal cartoner, entirely made with balcony construction, designed around three basic concepts: versatility, ergonomics and maximum efficiency in a small footprint. Because of its characteristics it is the ideal solution for packaging cosmetic and pharmaceutical products. |

|

MA255 Continous motion horizontal cartoner, entirely made with balcony construction, designed around three basic concepts: versatility, ergonomics and maximum efficiency in a small footprint. Because of its characteristics it is the ideal solution for packaging cosmetic and pharmaceutical products. The product is inserted into cartons continuosly, by means of 2 pushers placed opposite the operator side, perfoming 2 insertions at the same time. The 2 pushers are activated independently to make possible the action of only a single one, when needed. The mechanical output is up to 200 pcs/min. |

|

MA305 Continous motion horizontal cartoner, entirely made with balcony construction, designed around three basic concepts: versatility, ergonomics and maximum efficiency in a small footprint. Because of its characteristics it is the ideal solution for packaging cosmetic and pharmaceutical products. The product is inserted into cartons continuously, by means of 12 pushers placed opposite the operator side and following both product and carton transport chains. The mechanical output is up to 240 pcs/min. |

| MA302 | |

|

MA352 Continuous motion horizontal cartoner suitable for high speed packing in cartons of all products (blisters, bottles, rigid and squeezable tubes, sachets and trays) for both pharmaceutical and cosmetics markets. Entirely built with a balcony structure, this machine has all features and advantages of Marchesini cartoners: carton magazine in an optimum position, maximum accessibility, extremely fast changeover times, minimal maintenance. It is possible to collect the various rejects (product, carton, leaflet) in different containers, allowing improved recognition and control of the rejected items and easier, safer handling of rejects. |

|

MA357 Continuous motion horizontal cartoner, suitable for high speed packing in cartons of all products (as blisters, bottles, rigid and squeezable tubes, sachets and trays) for pharmaceutical and cosmetics markets. Entirely built with a balcony structure, this machine has all features and advantages of Marchesini cartoners: carton magazine in an optimum position, maximum accessibility, extremely fast changeover times, minimal maintenance. It is possible to collect the various rejects (product, carton, leaflet) in different containers, allowing improved recognition and control of the rejected items and easier, safer handling of rejects. |

| BA300 Argento Continuous motion cartoners combining the advantages of reduced overall dimensions with greater sturdiness and improved reliability. Balcony (cantilever) layout allows simple cleaning. Differentiated placement of mechanical and drive units as well as separated product handling are basis for a clean machine, assuring safety when executing lot changes. These cartoners have a completely enclosed structure with safety devices on all the opening parts to ensure overall protection and compliance with all the current safety regulations. |

|

|

BA400 Argento Continuous motion cartoner, combining the advantages of reduced overall dimensions with greater sturdiness and improved reliability. Balcony (cantilever) layout allows simple cleaning. Differentiated placement of mechanical and drive units as well as separated product handling are basis for a clean machine, assuring safety when executing lot changes. These cartoners have a completely enclosed structure with safety devices on all the opening parts to ensure overall protection and compliance with all the current safety regulations. |

Pharmaceutical thermoformer..:: Read More ::..

|

FB220 Automatic Deep Draw Thermoformer Mechanical intermittent motion fully automatic packaging machine, balcony construction, PC-controlled, stainless steel finish. Designed to suit pharmaceutical-production environments, it forms trays for vials, ampoules, syringes and similar products out of thermoformable films such as PVC, PET, Polystyrene (PS), PP, PLA, multilayer laminates etc. Its sturdiness, simple operation and the easy, tool-less change-over make it reliable, highly flexible, efficient and easy to service in a very small footprint. |

|

FB320 Mechanical intermittent motion fully automatic packaging machine, balcony construction, independent servo-driven stations, stainless steel finish, PC-controlled. Designed to fit into pharmaceutical-production environments, it thermoforms trays for vials, ampoules, syringes and similar products out of thermoformable films such as PVC, PET, Polystirene (PS), PP, PLA multilayer laminates etc. Its sturdiness, modular construction, simple operation and the easy, tool-less change-over make it reliable, highly flexible, efficient and easy to service. |

|

FBZ320 Mechanical intermittent motion fully automatic packaging machine, balcony construction, independent servo-driven stations, stainless steel finish, PC-controlled. Designed to fit into pharmaceutical-production environments, it thermoforms trays for vials, ampoules, syringes and similar products out of thermoformable films such as PVC, PET, Polystyrene (PS), PP, PLA multilayer laminates etc. Its sturdiness, modular construction, simple operation and the easy, tool-less change-over make it reliable, highly flexible, efficient and easy to service. |

|

FB420 Mechanical intermittent motion fully automatic packaging machine, balcony construction, independent servo-driven stations, stainless steel finish, PC-controlled. Designed to fit into pharmaceutical-production environments, it thermoforms trays for vials, ampoules, syringes and similar products out of thermoformable films such as PVC, PET, Polystyrene (PS), PP, PLA multilayer laminates etc. Its sturdiness, modular construction, simple operation and the easy, tool-less change-over make it reliable, highly flexible, efficient and easy to service. |

|

FBZ420 Mechanical intermittent motion fully automatic packaging machine, balcony construction, independent servo-driven stations, stainless steel finish, PC-controlled. This version is the ZERO-WASTE version of the FBZ420. Designed to fit into pharmaceutical-production environments, it thermoforms trays for vials, ampoules, syringes and similar products out of thermoformable films such as PVC, PET, Polystyrene (PS), PP, PLA multilayer laminates etc. Its sturdiness, modular construction, simple operation and the easy, tool-less change-over make it reliable, highly flexible, efficient and easy to service. |

|

Unica Robotized integrated tray packaging line, able to integrate the deep forming and carton packaging processes in one monobloc unit |

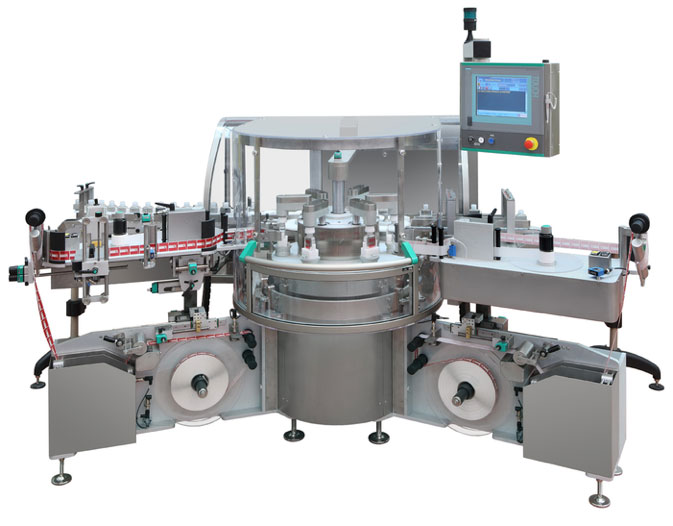

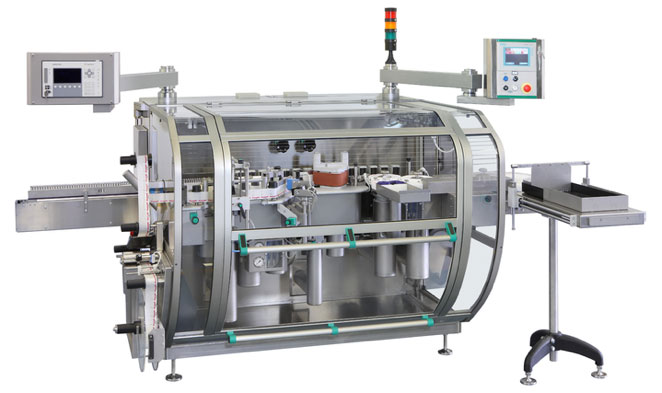

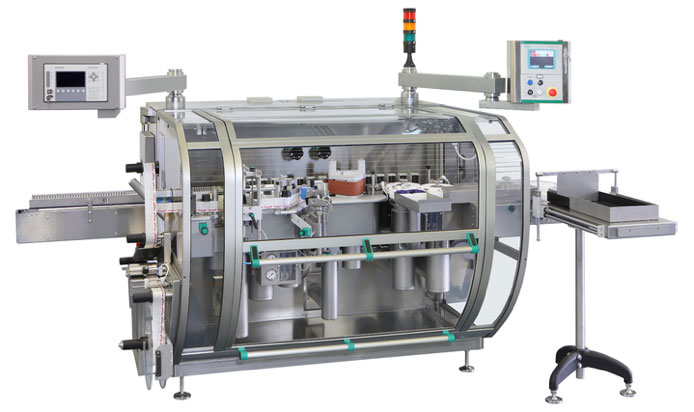

Pharmaceutical labellers for round container..:: Read More ::..

|

SL-F220 The SL-F220 is a medium speed labeler with a linear conveyor transport system and a worm screw vials indexing device, the machine has been designed to reduce to the minimum manual operations of size change. |

|

SL-F425 High speed labeler with a linear conveyor transport system and a worm screw vials indexing device, the machine has been designed to reduce to the minimum manual operations of size change. |

|

RE302 New Re 302 is an automatic rotary labelling machine used to apply self-adhesive or glued outsert labels that can be equipped with 1 to 2 labels dispensing heads, based on the machine model and on the diameter of the carousel installed. RE 302 is designed to position and label oval, shaped or cylindrical containers made of glass, plastic and/or metal at high speed. Built focusing on ergonomics, reducing the frame so that the operator can stand nearer all the heads installed on the machine and to ensure ease-of-access to be able to service, clean it and monitor the production flow. Machine output: 300 pieces/min. |

|

RE202 New Re 202 is an automatic rotary labelling machine used to apply self-adhesive or glued outsert labels that can be equipped with 1 to 2 labels dispensing heads, based on the machine model and on the diameter of the carousel installed. RE 202 is designed to position and label oval, shaped or cylindrical containers made of glass, plastic and/or metal at high speed. Built focusing on ergonomics, reducing the frame so that the operator can stand nearer all the heads installed on the machine and to ensure ease-of-access to be able to service, clean it and monitor the production flow. |

|

RE402 New RE402 is an automatic rotary labelling machine used to apply self-adhesive or glued outsert labels that can be equipped with 1 to 2 labels dispensing heads, based on the machine model and on the diameter of the carousel installed. RE 402 is designed to position and label oval, shaped or cylindrical containers made of glass, plastic and/or metal at high speed. Built focusing on ergonomics, reducing the frame so that the operator can stand nearer all the heads installed on the machine and to ensure ease-of-access to be able to service, clean the machine and monitor the production flow. Unit built pursuant to cGMP standards. |

|

BL-F600 Automatic self adhesive labelling machine suitable to apply one label on vials, bottles or similar round containers. The machine can work in line or as a stand-alone, equipped with appropriate feeding/unscrambling systems. |

|

BL-F425 Automatic self adhesive labelling machine suitable to apply label on vials, bottles or similar round containers. The machine can work in line or as a stand-alone, equipped with appropriate feeding/unscrambling systems. |

|

RL-F300 Automatic self-adhesive labelling machine, for high speed labelling of flat bottom ampoules, vials or similar round containers, external diameter from 8 to 32 mm. It can work in-line with other packaging machines or as free standing unit with a tray infeed and outfeed arrangement. |

|

RL-F500 Automatic self-adhesive labelling machine, for high speed labelling of flat bottom ampoules, vials or similar round containers, external diameter from 8 to 32 mm. It can work in-line with other packaging machines or as free standing unit with a tray infeed and outfeed arrangement. |

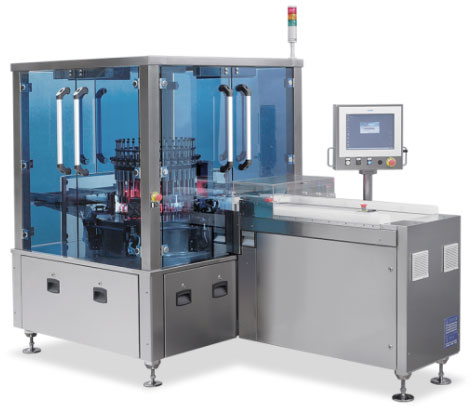

Inspection Machinery..:: Read More ::..

|

A1 A1 represents the first automatic machine for the inspection of liquid, freeze dried and powder products with extremely reduced format change parts. Inspect System: Automatic, Semi Automatic Container type: Vials, Ampoules, Cartridges & Syringes Product to be Inspected: Waterlike, Freeze-dried, Suspensions & Oily Nominal Speed: 3.000 |

|

A30 This machine has been designed to be inserted downstream from filling and sterilizing lines and upstream from labelling and packaging systems. Once loaded on the conveyor belt, the containers (ampoules, vials, cartridges) are sent to the inspection path, where all the inspections are carried out. Process control is totally automatic. Inspect System: Automatic Container type: Vials, Ampoules, Cartridges Product to be Inspected: Waterlike, Freeze-dried, Suspensions & Oily Nominal Speed: 12.000 |

|

A35 – A35 LD Brevetti A35, a technically advanced and compact inspection machine, is capable of inspecting products at a maximum speed of 300 pieces per minute. It can inspect liquids (including oily solutions and suspensions) and freeze-dried pharmaceutical products contained in vials, ampoules or cartridges. Inspect System: Automatic Container type: Vials, Ampoules & Cartridges Product to be Inspected: Waterlike, Freeze-dried, Suspensions & Oily Nominal Speed: 18.000 |

|

A50 is an automatic and flexible machine dedicated to massive inspection of ampoules, vials and cartridges filled with liquid (including oily solutions and suspensions) and freeze-dried pharmaceutical products. The model is available in two different configurations: A50-150 and A50-300, covering respectively productivities up to 150 and 300 pieces per minute. Inspect System: Automatic Container type: Vials, Ampoules & Cartridges Product to be Inspected: Waterlike, Freeze-dried, Suspensions & Oily Nominal Speed: 9.000 - 18.000 |

|

A50-450 + A50–450 LD Designed as a further declination of the A50 machine, with its speed up to 450 pieces per minute, the A50-450 machine represents the first choice for high productivity processes for liquid pharmaceutical products. Inspect System: Automatic Container type: Vials, Ampoules & Cartridges Product to be Inspected: Waterlike, Suspensions & Oily Nominal Speed: 27.000 |

|

BH-S600 Conceived to satisfy the most demanding production lines, the new “BH-S600” can inspect ampoules, vials and cartridges filled with liquid products at the maximum speed of 36.000 units per hour. Inspect System: Automatic Container type: Vials, Ampoules & Cartridges Product to be Inspected: Waterlike, Suspensions & Oily Nominal Speed: 36.000 |

|

BL-S300 Robust construction, high productivity and reliable performances distinguish BL-S300 as the perfect response to the Large Volume Parenteral inspection requirements. Inspect System: Automatic Container type: Vials & LVP Product to be Inspected: Water-like Nominal Speed: 18.000 |

|

K15 – K15-600 K15 machine is dedicated to the inspection of pre-filled syringes. Available in different configurations, it covers a productivity from 200 to 600 pieces per minute and a diameter from a min. of 6,85 mm to a max. of 14,45 mm. Inspect System: Automatic Container type: Syringes Product to be Inspected: Waterlike & Suspensions Nominal Speed: 24.000 - 36.000 |

|

K15-C K15-C is the machine dedicated to the inspection of pre-filled syringes designed to be inserted downstream from filling and sterilizing lines and upstream from labelling and packaging systems. Inspect System: Automatic Container type: Syringes Product to be Inspected: Waterlike & Suspensions Nominal Speed: 12.000 - 24.000 |

|

K32S - K32SLD - K32-600 K32S machine is dedicated to high speed inspection of vials, ampoules and cartridges filled with pharmaceutical liquid (including oily solutions and suspensions) and freeze-dried products. Available in multiple configurations, it covers a productivity range from 400 to 600 pieces per minute. Inspect System: Automatic Container type: Vials, Ampoules & Cartridges Product to be Inspected: Waterlike, Freeze-dried, Suspensions & Oily Nominal Speed: 24.000 - 36.000 |

|

LDM The High voltage leak detection technology is available as a stand-alone machine or as a compact modular system which can be integrated in new and existing lines. LDM uses a well-known and widely proven detection principle based on the measurement of electrical conductivity of sealed containers using a high voltage electric field. The system measures the electrical conductivity of the “container + liquid product” placed between two electrodes. Any conductivity variation due to glass or sealing defects is detected. Inspect System: Automatic Container type: Vials, Ampoules, Cartridges Product to be Inspected: Waterlike, Suspensions & Oily Nominal Speed: 24.000 |

Tablet press machinery..:: Read More ::..

|

XL-100 The XL 100 is an innovative tablet press for product development, scale-up, and clinical batch production. The XL 100 offers a new standard in GMP, extreme accessibility to the compression zone, an exchangeable turret for maximum flexibility, and a combination of quick-disconnects and smooth surfaces that permit fast cleaning and changeover. |

|

XL-200 The XL 200 is a robust, high-speed rotary press which is ideal for scale-up operation and the production of mid-sized charges. The XL 200 offers an exchangeable turret capability and a new standard in GMP, with extreme accessibility to the compression zone and a combination of quick-disconnects and smooth surfaces that permit streamlined cleaning and changeover. |

|

XL 400 SFP The XL 400 SFP is a single-sided high-speed rotary tablet press dedicated to single-layer tablet production. The XL 400 SFP offers streamlined product changeover, unique accessibility to the compression zone and extremely quiet operation. All major technical components are placed in the rear cabinet (including the main motor) avoiding heat transfer to the product. The robust design offers 100 kN pre and main compression capability. A unique compression dwell bar between pre and main compression dramatically extends dwell time for the most difficult products. |

|

XL 400 MFP The XL 400 MFP (Multi-Function Platform) tablet press offers an innovative and flexible design platform that permits the production of all tablet formats on a single tablet press, including single-layer, bi-layer and tri-layer. The XL 400 MFP features a modified carrier place and head piece that permits the installation of a wide range of compression roller modules, feeder modules, and cam track modules that permit a “plug and play” approach for maximum versatility. The result is an unprecedented advancement in tablet press technology which permits maximum efficiency and utilization from a single tablet press. |

|

XL 800 The XL 800 is the highest output tablet press in the world, offering a single-layer and bi-layer capability. The exchangeable turret design permits the production of any tablet size on a single machine. The unique mechanical design isolates vibration in the compression zone to permit the lowest noise operation, even at the higher press speeds and compression forces. The XL 800 is a proven, reliable workhorse for high volume, 24/7 operation. |

|

XM 12 The XM 12 tablet press is a small-scale single-layer and bi-layer press which is ideal for product development, clinical production, and mid-range production. The XM 12 tablet press offers an exchangeable turret design to permit the production of any tablet size. The conversion between single-layer and bi-layer operation can be completed very easily. The XM 12 control system offers a unique first layer sampling capability, and the option for integrated press force control, single-tablet rejection, and integrated data acquisition and analysis. |

|

XP 1 The XP 1 research tablet press is a single punch machine which is specifically designed to permit initial feasibility, screening, and solid product characterization for single or multi-layer tablets. The XP 1 permits very small material quantities to be utilized and characterized very quickly with a minimum of set-up and cleaning time. The XP 1 offers a proven, rugged, and portable design, which insures precision operation over the long term. |

|

XT 600 The XT 600 combines key features from proven KORSCH technology with a simple, modular, and cost-efficient design to offer a new standard in high-volume production equipment. The robust and elegant design features a simplified and streamlined platform for both semi-attended and fully automated production. The completely redesigned control system interface combines an intuitive HMI environment with an unprecedented level of on-line help and assistance to advise the user in every aspect of the machine operation. A 19-inch touch screen display supports gestures to permit move, zoom, and scroll functions to simplify and enhance the user experience. |

|

TRP 700 The TRP 700 offers a rugged and proven design for the production of AA and AAA batteries, and a range of other technical applications. The TRP 700 offers an innovative press tool design to facilitate deep fill depths, and high compression and ejection forces. The TRP 700 offers a 100 kN press force capability and can produce a maximum tablet diameter of 64 mm. The TRP 700 can be combined with a ring insertion and post compaction equipment line for high-speed automated battery production. |

|

TRP 900 The TRP900 offers a rugged and proven design for the production of AA, AAA, C, and D-size batteries. and a range of other heavy-tonnage technical applications. The TRP900 offers an innovate press tool design to facilitate deep fill depths, and high compression and ejection forces. The TRP900 offers a 200 kN press force capability, and can product a maximum tablet diameter of 64 mm. The TRP900 can be combined with a ring insertion and post compaction equipment line for high-speed automated battery production. |

Behsan Parsian Sanat Company Ltd. is a manufacturer’s representative company head-officed in Tehran, providing nationwide sales and client support throughout Iran; having international offices located in Vancouver, Canada.

Behsan Parsian Sanat Company Ltd. is a manufacturer’s representative company head-officed in Tehran, providing nationwide sales and client support throughout Iran; having international offices located in Vancouver, Canada.